My neighbor Mark’s tankless water heater installation became a complex puzzle of venting requirements. His experience showed that proper venting is crucial for home comfort and safety. It’s not just a technical detail, but a critical aspect of the installation process.

Tankless water heater venting is more challenging than many homeowners realize. It involves precise measurements, specific materials, and strict safety protocols. Proper vent pipe installation goes beyond simply connecting pipes.

Professional installation is essential for tankless water heaters. These systems need careful planning for efficient operation and safety. Understanding venting nuances can prevent potential hazards and save money in the long run.

Key Takeaways

- Tankless water heaters require specialized venting techniques

- Professional installation ensures optimal performance and safety

- Proper venting extends the 20-year lifespan of the unit

- Correct venting eliminates potential combustion byproduct risks

- Regular maintenance is essential for long-term efficiency

Understanding Tankless Water Heater Venting Fundamentals

Tankless water heaters offer a modern approach to home water heating. Venting plays a crucial role in their performance and safety. Proper venting ensures efficient operation and protects homeowners from potential risks.

Types of Venting Systems

Tankless heater exhaust systems come in various configurations. Each design meets specific installation requirements.

- Sealed combustion venting

- Direct vent systems

- Power vent configurations

- Concentric vent designs

Safety Considerations and Code Compliance

“Proper venting is not just a recommendation, it’s a critical safety requirement for tankless water heaters.”

Installing tankless water heater venting requires following local building codes. Manufacturer guidelines must also be adhered to. Safety is paramount in these installations.

Critical safety considerations include:

- Preventing gas buildup

- Ensuring proper exhaust removal

- Maintaining optimal combustion efficiency

Basic Venting Components

Knowing the key components of tankless water heater venting is crucial. This knowledge ensures proper installation and performance.

| Component | Function | Material Considerations |

|---|---|---|

| Vent Collar | Connection point for exhaust system | Stainless steel or specialized alloys |

| Vent Pipes | Exhaust gas transportation | PVC or specialized metal materials |

| Termination Cap | Prevents external elements from entering | Weather-resistant design |

Proper installation and maintenance of these components are crucial for safe and efficient tankless water heater operation.

Benefits of Proper Tankless Water Heater Venting

Proper tankless water heater venting boosts your home’s hot water system. It offers amazing benefits beyond traditional heating methods. Good venting helps homeowners save energy and enjoy non-stop hot water.

Professional venting does more than manage exhaust. It brings key advantages to your home. Let’s look at these benefits:

- Enhanced energy efficiency through precise combustion management

- Guaranteed continuous hot water supply without interruption

- Improved safety by removing harmful combustion byproducts

- Extended equipment lifespan

“Proper venting is the foundation of a high-performing tankless water heating system.”

Tankless water heaters outperform traditional tank systems. Check out these impressive stats:

| Performance Metric | Tankless Water Heaters | Traditional Tank Heaters |

|---|---|---|

| Operational Lifespan | 20 years | 10-15 years |

| Energy Efficiency | 95% efficient | 60-70% efficient |

| Hot Water Supply | Continuous | Limited |

Good tankless water heater venting gives you reliable, efficient hot water. Professional installation ensures optimal venting. This means non-stop hot water and lower energy bills.

Essential Venting Requirements and Guidelines

Proper vent pipe installation is crucial for safe tankless water heater operation. Gas-powered units need careful ventilation for optimal performance and safety. Understanding ventilation guidelines helps homeowners maintain their systems effectively.

Minimum Clearance Requirements

Specific clearance guidelines must be followed when installing a tankless water heater. Keep at least 12 inches between fresh air and exhaust vents. Ensure proper distance from combustible materials.

Respect local building code regulations for direct vent termination.

- Maintain at least 12 inches between fresh air and exhaust vents

- Ensure proper distance from combustible materials

- Respect local building code regulations for direct vent termination

Vent Pipe Material Selection

Choosing the right vent pipe materials is key for long-term performance. Different tankless water heaters need specific materials. Condensing units can use plastic vents due to lower exhaust temperatures.

Standard units require metal category-3 piping for higher temperatures. Stainless steel pipes are recommended for durability.

- Condensing units: Can use plastic vents due to lower exhaust temperatures

- Standard units: Require metal category-3 piping for higher temperatures

- Stainless steel pipes recommended for durability

Installation Best Practices

Power vent kits and proper installation techniques are vital for safe operation. Always vent to the outside. Avoid sharing vent piping with other appliances.

Follow the manufacturer’s specific installation guidelines.

- Always vent to the outside

- Avoid sharing vent piping with other appliances

- Follow manufacturer’s specific installation guidelines

“Proper ventilation is the key to maintaining the efficiency and safety of your tankless water heater.” – HVAC Professional

Careful attention to venting requirements ensures your tankless water heater operates safely and efficiently for years to come.

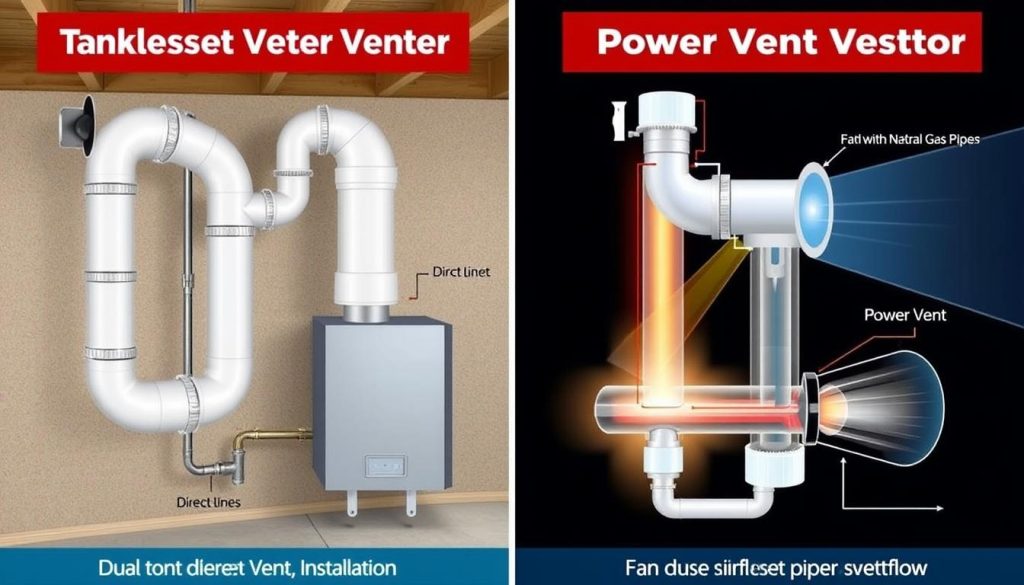

Direct Vent vs Power Vent Systems

Tankless water heaters need the right venting system for top performance. Direct vent and power vent systems offer unique benefits for homeowners. Let’s explore these options for your new water heating solution.

Direct vent systems use two separate vents: one for intake and one for exhaust. They draw outside air for combustion, perfect for well-sealed homes. Sealed combustion venting ensures safety and energy efficiency.

“Choosing the right venting system can reduce energy consumption by up to 50%”

Key Differences Between Venting Systems

| Feature | Direct Vent | Power Vent |

|---|---|---|

| Air Intake | Outside air | Indoor air |

| Electricity Requirement | No | Yes (for blower) |

| Installation Flexibility | Limited | High |

| Initial Cost | Lower | Higher |

Power vent kits offer more installation options, especially in homes without traditional chimneys. They use indoor air for combustion and only need an exhaust vent. These systems have some important factors to consider.

- Additional electricity costs for the blower

- Potential noise from the ventilation system

- Easier installation in diverse home layouts

The U.S. tankless water heater market is growing fast at 8.7% annually. This shows rising interest in efficient water heating. Homeowners should weigh their needs carefully when choosing between direct and power vent systems.

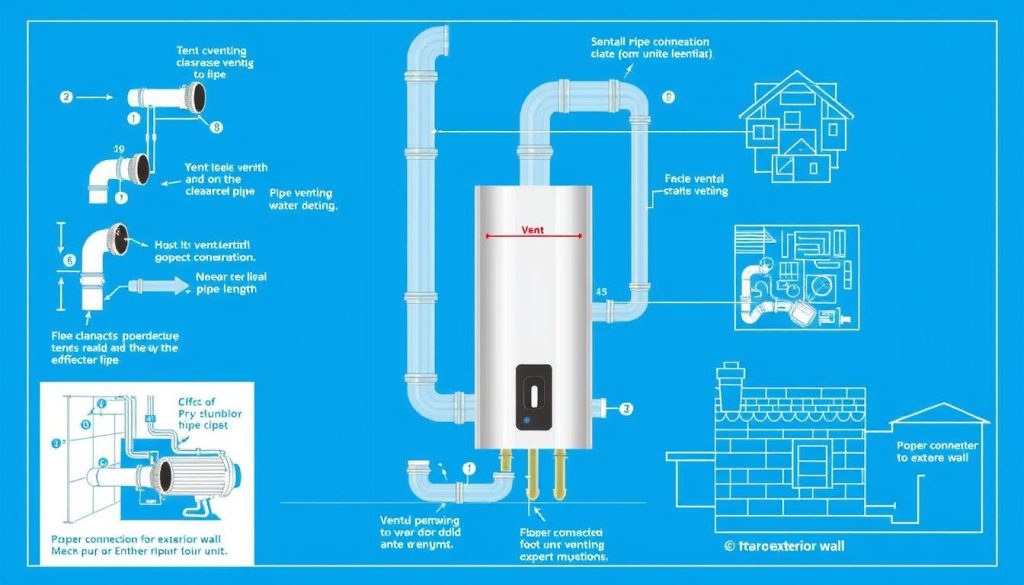

Tankless Water Heater Venting Options and Configurations

Understanding tankless water heater venting is key for optimal performance and safety. Modern units offer flexible solutions for various home setups. These options adapt to different environmental needs.

Homeowners and installers can choose from several venting configurations. Each option has its own benefits. Let’s explore these strategic venting solutions.

Sidewall Venting Solutions

Sidewall venting offers an efficient alternative to roof venting. It allows direct exhaust through exterior walls. This method makes installation more flexible for different home layouts.

Key benefits include reduced installation complexity and lower overall venting costs. It also improves accessibility for maintenance.

- Reduced installation complexity

- Lower overall venting costs

- Improved accessibility for maintenance

Vertical Roof Venting Methods

Vertical roof venting remains a classic approach for tankless water heaters. This method needs precise installation with proper rain caps. These caps prevent water intrusion.

Professional installers recommend the following steps:

- Ensuring proper vertical alignment

- Using high-quality rain caps

- Maintaining recommended clearance distances

Concentric Vent Systems

Concentric vent pipes are a cutting-edge solution for tankless water heaters. These systems use a pipe-within-a-pipe design. This setup enhances both safety and efficiency.

| Vent Type | Efficiency | Safety Rating |

|---|---|---|

| Concentric Vents | Up to 96% | High |

| Traditional Vents | 80-85% | Moderate |

“Selecting the right venting configuration can dramatically improve your tankless water heater’s performance and longevity.” – HVAC Experts

The U.S. tankless water heater market is growing fast. It’s expected to increase by 8.7% annually. This growth makes understanding venting options crucial for homeowners seeking energy-efficient solutions.

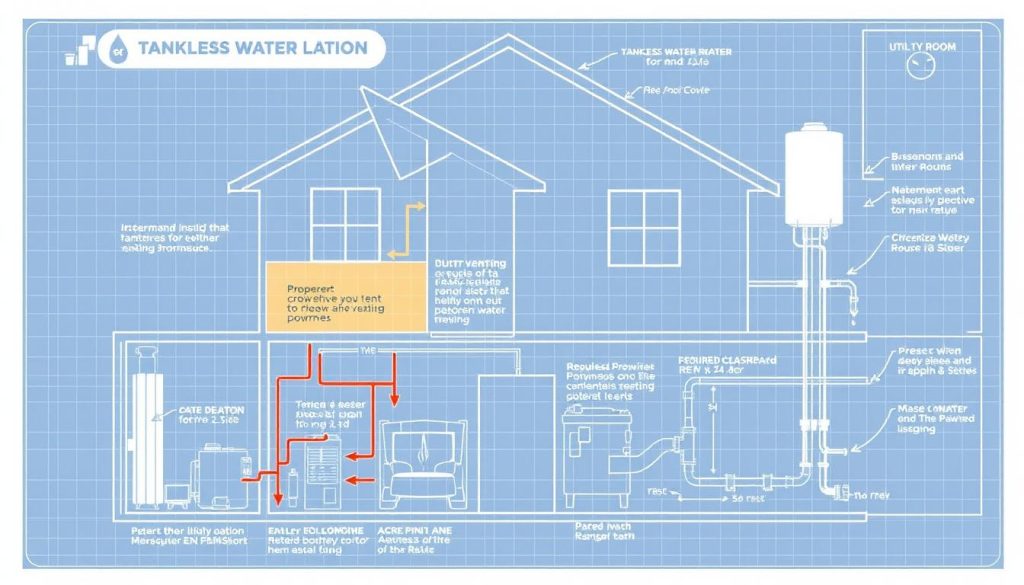

Installation Planning and Location Considerations

Choosing the right spot for your tankless water heater is crucial. It affects performance and lifespan. The U.S. Department of Energy stresses smart installation for maximum energy savings.

Key factors for tankless water heater setup include:

- Proximity to water and power sources

- Adequate ventilation requirements

- Compliance with local building codes

- Accessibility for maintenance

Homeowners should think about these important aspects:

- Indoor vs. Outdoor Installation: Gas-powered units require specific ventilation considerations

- Electrical power compatibility

- Gas line capacity and potential upgrades

- Clearance from combustible materials

Proper installation planning can enhance your tankless water heater’s efficiency by up to 24% compared to traditional storage tank models.

Gas-powered tankless heaters often need upgraded gas lines. This usually means switching from 1/2-inch to 1-inch pipes. The change accommodates higher BTU needs (90k to 130k BTU/H).

Professional installation ensures safety, performance, and compliance. It also helps maximize potential energy savings.

- Safe venting configuration

- Optimal unit performance

- Compliance with manufacturer guidelines

- Potential energy savings

Tankless water heater venting isn’t universal. Each setup needs careful planning. Consider your home’s layout and hot water needs.

Venting Distance Specifications and Requirements

Safe tankless water heater installation requires proper venting. Correct vent pipe setup ensures optimal performance and safety. It prevents potential hazards and keeps the system running efficiently.

Maximum Vent Length Guidelines

Venting distances for tankless water heaters vary by model and manufacturer. Key factors include pipe diameter, material, and allowable bends. Horizontal and vertical configurations also affect maximum vent length.

Most tankless heaters allow up to 65 equivalent feet of PVC piping. This applies to both exhaust and air intake pipes. Such flexibility enables various installation options in homes.

- Pipe diameter and material specifications

- Number of allowable bends and elbows

- Horizontal and vertical venting configurations

Termination Point Regulations

Direct vent termination needs careful attention to clearance requirements. Important factors include distance from windows and doors. Clearance from exterior building features is also crucial.

Proper ventilation prevents exhaust gas recirculation. Follow manufacturer guidelines for approved vent termination locations. This ensures safe and efficient operation.

- Minimum distance from windows and doors

- Clearance from exterior building features

- Proper ventilation to prevent exhaust gas recirculation

Approved vent termination locations must follow manufacturer guidelines to ensure safe and efficient operation.

Proper Support and Spacing

Vent pipe installation requires precise support and spacing. This maintains structural integrity over time. Use appropriate pipe supports every 4-5 feet.

Prevent sagging or stress on connection points. Maintain consistent pipe alignment throughout the system. These practices ensure long-lasting performance.

- Using appropriate pipe supports every 4-5 feet

- Preventing sagging or stress on connection points

- Maintaining consistent pipe alignment

| Venting Specification | Recommended Requirements |

|---|---|

| Vent Pipe Material | Schedule 40 Solid Core PVC |

| Maximum Pipe Length | 65 Equivalent Feet |

| Pipe Diameter | 2″ or 3″ (Model Specific) |

Regular venting system checks prevent obstructions and ensure top performance. Experts recommend yearly inspections to maintain optimal functionality. This keeps your tankless water heater running smoothly and safely.

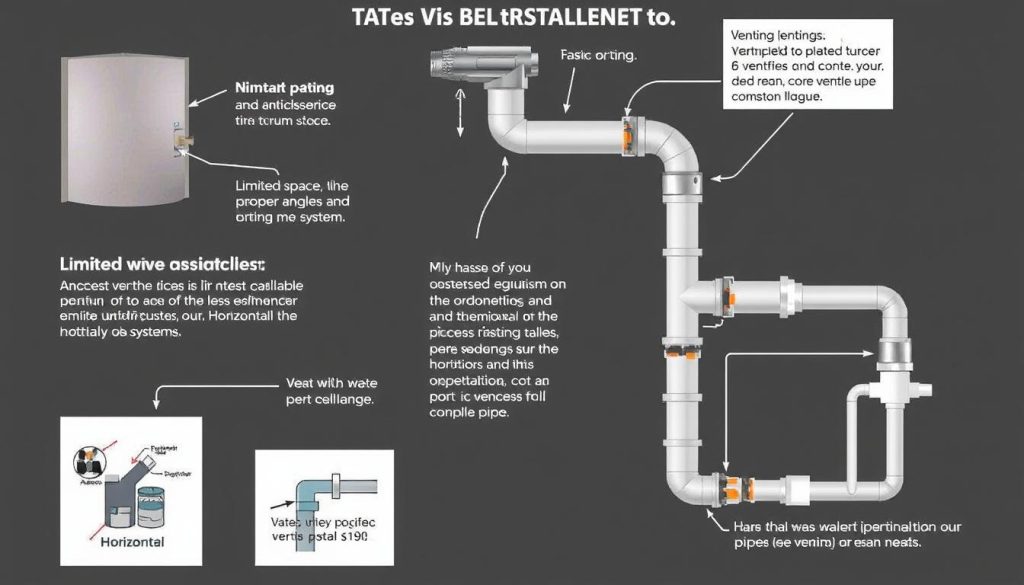

Common Venting Challenges and Solutions

Tankless water heater venting poses unique challenges for homeowners. Careful navigation is key for successful installation and long-term performance. Understanding these obstacles ensures your heating system works efficiently.

“Proper venting is not just about compliance, but ensuring the safety and efficiency of your tankless water heater.”

Venting challenges can arise from various factors, including:

- Limited installation space

- Complex home configurations

- Existing structural limitations

- Mineral buildup in exhaust systems

Mineral buildup is a major threat to tankless water heater venting. Hard water can leave calcium and magnesium deposits that obstruct exhaust paths. Studies show that water hardness directly affects mineral buildup.

Installation solutions for venting challenges include:

- Utilizing condensing units for extended vent runs

- Implementing creative termination points

- Using pipe covers to conceal venting

- Installing water softeners to reduce mineral accumulation

| Venting Challenge | Recommended Solution |

|---|---|

| Exhaust System Blockages | Annual system flushing and descaling |

| Limited Ventilation Space | Concentric vent systems |

| Mineral Buildup | Water softener installation |

HVAC experts suggest regular maintenance to prevent venting issues. Addressing challenges early can boost performance and extend your tankless water heater’s life. Proactive care ensures your system runs smoothly for years.

Maintenance and Inspection of Venting Systems

Maintaining your tankless water heater’s venting system is vital for safe and efficient operation. It prevents hazards and extends the unit’s life. Regular upkeep ensures your heating system performs at its best.

Regular Maintenance Schedule

A thorough maintenance routine for tankless heater exhaust systems should include:

- Annual professional inspection

- Checking vent pipes for obstructions

- Verifying proper clearances around venting components

- Cleaning or replacing air filters

Signs of Venting Problems

Homeowners should be alert for these warning signs of venting issues:

- Unusual odors near the water heater

- Excessive condensation around vent pipes

- Reduced hot water performance

- Visible corrosion or damage to vent components

“Detecting venting problems early can prevent costly repairs and potential safety risks.”

Professional Inspection Guidelines

A professional inspection of your tankless water heater venting system should thoroughly assess:

- Vent pipe material integrity

- Proper alignment and support

- Clearance from combustible materials

- Gas pressure and exhaust flow

Experts suggest yearly professional inspections for your tankless water heater venting system. This ensures top performance and safety for your heating unit.

Conclusion

Proper tankless water heater venting is vital for home comfort and safety. Professional installation is crucial due to complex venting requirements. Correct venting ensures optimal performance, efficiency, and longevity of your system.

Modern tankless water heaters are highly energy-efficient. They can achieve up to 85 percent thermal efficiency, outperforming traditional tank models. Correct venting strategies help reduce energy consumption while providing consistent hot water.

Safety is the top priority in tankless water heater installation. Follow local building codes and manufacturer guidelines to prevent hazards like carbon monoxide leakage. Professional installation and yearly exhaust system checks are essential for peak performance and safety.

Understanding tankless water heater venting is a worthwhile investment. Prioritize professional guidance and regular maintenance for your system. This approach ensures reliability, energy efficiency, and peace of mind for your hot water solution.